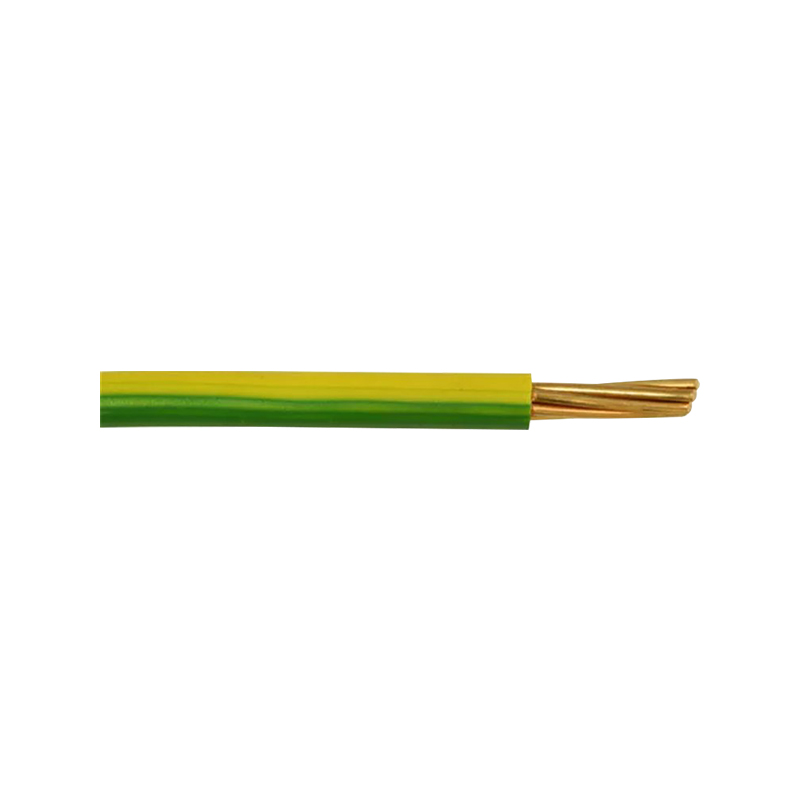

1.The conductor is crafted from high-grade oxygen-free copper, offering excellent electrical conductivity and minimal heat generation, making it suitable for continuous load operation.

2.The insulation layer uses premium plastic material that is resistant to abrasion, non-flammable, and designed for a long service life.

3.Ideal for concealed installations, the cable features a flexible stranded conductor that bends easily without breaking, making it one of the most commonly used wiring options in residential electrical systems.

4.The high-quality copper strands provide enhanced softness and durability, making handling and installation more efficient and user-friendly.

5.The insulation sheath maintains a consistent thickness, helping to prevent electrical breakdown and reducing the risk of ignition, ensuring safe operation.

6.Manufactured with high-performance PVC, the cable is flame-retardant, corrosion-resistant, and capable of self-extinguishing away from fire sources. Models such as ZR-BVR and HH-BVR are available, and free samples can be provided.

Scope of Application

This type of cable is widely used in construction projects, security monitoring systems, household electrical appliances, LED displays, and more. It is suitable for wiring applications in power plants, home devices, instrumentation, and telecommunications equipment operating at AC voltages below 450/750V.

PVC Earthing Copper Stranded Wire

-

-

Data Of PVC Earthing Copper Stranded Wire

Cross-Section mm2Structure (No./mm) Approx. Overall Diameter (mm)DC Conductor Resistance at 20°C (Ω/km) Abruption Force (N) Gross Weight (kg/km) 16 7/1.70 5.10 1.1460 5760 143.3 25 7/2.12 6.36 0.7293 8870 222.8 35 7/2.50 7.50 0.5245 12220 309.8 50 7/3.00 9.00 0.3642 17320 446.1 70 19/2.12 10.60 0.2706 24080 604.7 95 19/2.50 12.50 0.1943 33160 840.9 120 19/2.80 14.00 0.1549 11170 1055 150 19/3015 15.75 0.1224 51710 1335 185 37/2.50 17.50 0.1000 64570 1651 240 37/2.85 19.95 0.0770 83060 2145 300 37/3.15 22.05 0.0630 100700 2621 400 61/2.85 25.65 0.0467 136900 3541 -

about us

Our Story

Xinchang TuAn Machinery Co., Ltd.Rooted in the past, facing the future?

Based on customer needs, connect the products and technologies required by customers with the scientific research capabilities of universities to achieve innovation based on customer needs.

TuAn is famous China PVC Earthing Copper Stranded Wire manufacturers and PVC Earthing Copper Stranded Wire factory, the company continuously strengthens cooperation with upstream and downstream enterprises, rapidly expands comprehensive service capabilities, and transforms from a single lightning protection enterprise to a comprehensive large-scale project supporting enterprise. After years of accumulation, TuAn has formed a stable customer base covering important fields such as petroleum and petrochemical, high-speed rail, and electric power.

Recommended Products

What is the overall durability and safety of PVC earthing copper stranded wire?

The overall durability and safety of the PVC earthing copper stranded wire produced by Xinchang TuAn Machinery Co., Ltd. depend on several key factors related to its design, materials, and manufacturing processes.

Copper is highly conductive and corrosion-resistant, making it ideal for earthing applications. The use of PVC earthing stranded copper improves flexibility and allows the wire to better withstand mechanical stress during installation and operation.The copper strands are designed to maintain high electrical conductivity over the long term, reducing the risk of performance degradation.

The PVC insulation provides excellent protection against environmental factors such as moisture, dust, and chemical exposure. It also helps in preventing accidental electrical contact, thereby enhancing safety.PVC is known for its mechanical strength and abrasion resistance, making it highly durable under normal usage conditions. However, its resistance to UV radiation, extreme temperatures, and long-term exposure to outdoor elements (such as sunlight or rain) may vary, depending on the specific formulation used.

The copper wire’s resistance to corrosion ensures that it maintains its conductivity over time. The PVC insulation also acts as a barrier against moisture and chemicals that could otherwise cause corrosion or degradation of the copper core.The wire is designed for earthing, ensuring that it can handle low-resistance grounding in a variety of electrical systems, preventing the risk of equipment damage or electrical hazards.

The stranded construction of the wire allows it to bend and flex without breaking, making it more resilient to physical stress during installation and in service. This is especially important in earthing applications, where wires are often subjected to movement or strain.However, it’s important to ensure that the wire is not overstretched or damaged during installation to maintain its full durability.

PVC insulation helps prevent electrical faults and accidental electric shocks by providing an extra layer of protection against electrical exposure.The wire meets safety standards to ensure safe grounding for electrical systems, preventing the risk of electrical fires, equipment damage, or electrocution.

The wire is likely designed to meet industry standards such as IEC, BS, UL, or ISO for both electrical safety and mechanical integrity. These standards ensure that the wire performs well under normal conditions and can handle the electrical loads required for earthing applications.

The combination of copper and PVC ensures that the wire maintains its performance over the long term. However, regular inspections and maintenance are recommended to ensure the wire's continued effectiveness in grounding systems, especially in environments where it may be exposed to harsh conditions (e.g., high temperatures, humidity, or industrial chemicals).

The PVC earthing copper stranded wire offers excellent durability due to the high-quality copper core and PVC insulation, making it highly resistant to mechanical stress, corrosion, and environmental damage. Its safety features, such as electrical insulation, make it suitable for use in grounding and earthing systems where reliable and long-lasting performance is critical. Proper installation and regular maintenance are essential to maximizing the wire's durability and safety in service.

English

English 简体中文

简体中文