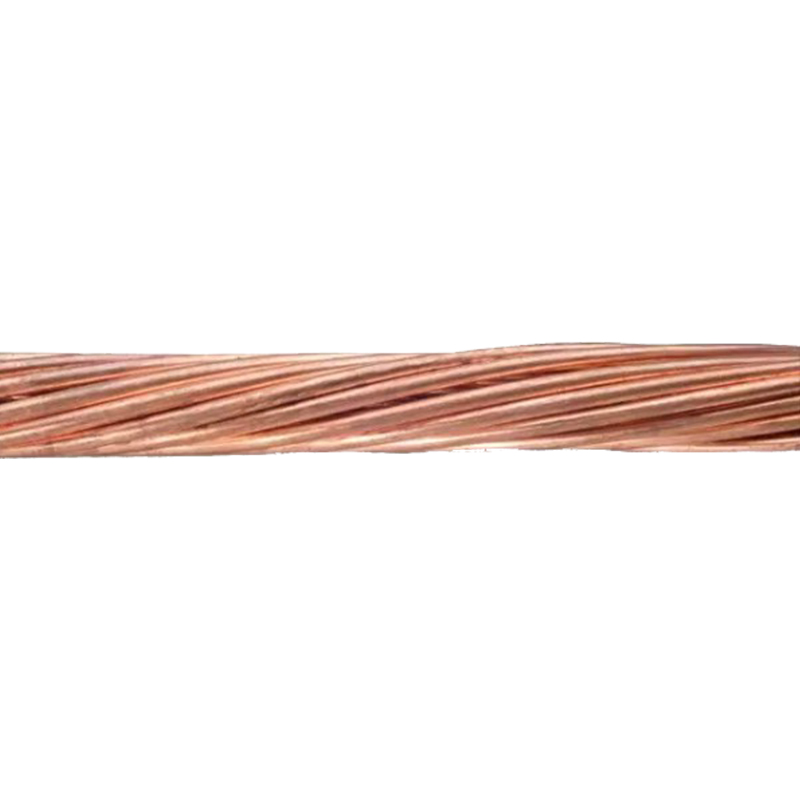

The copper stranded wire is made of high pure copper, which is used in power equipment and earthing system

The stranded wire can be hard drawn copper wire, soft drawn copper wire, tinned copper wire as request

Earthing Copper Stranded Wire

-

-

Data Of Earthing Copper Stranded Wire

Nominal section areamm2Theoretical cross sectionmm2Structure OD Resistance under 20°CΩ/km ≤Weight kg/km Strands no*wire diameter mm TJR-1 10 10.01 7*1.35 4.05 1.83 90 16 15.83 7*1.7 5.1 1.16 143 25 24.7 7/2.12 6.36 0.75 223 35 34.35 7/2.5 7.5 0.55 309 50 49.48 7/3 9 0.4 446 50 47.3 19/1.78 8.9 0.4 446 70 67.07 19/2.12 10.6 0.276 607 95 93.27 19/2.5 12.5 0.199 844 120 116.99 19/2.8 14 0.158 1097 150 148.07 19/3.15 15.75 0.128 1340 150 147.12 37/2.25 15.75 0.128 1340 185 181.62 37/2.5 17.5 0.104 1670 240 236.04 37/2.85 19.95 0.07 2140 300 288.35 37/3.15 22.05 0.063 2615 400 389.14 61/2.85 25.65 0.0484 3536 Performance &Data of Tinned Copper Stranded Wire

Item

Data

Material

99.98% pure copper ,tinned surface

Tin content

≥0.001%

Copper content

≥99.969%

ρ20(Ω·mm2/m

Resistance of single wire ρ20(Ω·mm2/m)

≤0.01754

Bent test(Bent 90°)

No crack

Elongation rate of single wire(%)

0.6~1%

Melt point(℃)

1083.4+0.2

Surface

Shine, no residue, no oil, non-cross, no jumper

-

about us

Our Story

Xinchang TuAn Machinery Co., Ltd.Rooted in the past, facing the future?

Based on customer needs, connect the products and technologies required by customers with the scientific research capabilities of universities to achieve innovation based on customer needs.

TuAn is famous China Earthing Copper Stranded Wire manufacturers and Earthing Copper Stranded Wire factory, the company continuously strengthens cooperation with upstream and downstream enterprises, rapidly expands comprehensive service capabilities, and transforms from a single lightning protection enterprise to a comprehensive large-scale project supporting enterprise. After years of accumulation, TuAn has formed a stable customer base covering important fields such as petroleum and petrochemical, high-speed rail, and electric power.

Recommended Products

What are the conductive advantages of using earthing copper stranded wires in grounding systems?

Using earthing copper stranded wires in Xinchang TuAn Machinery Co., Ltd.'s grounding system provides several key conductive advantages that significantly improve the system's safety, efficiency, and longevity.

High Conductivity: Copper is one of the best conductors of electricity, with a conductivity rating of around 100% on the International Annealed Copper Standard (IACS). This ensures that earthing copper stranded wires have minimal resistance, facilitating the quick and efficient dissipation of electrical currents into the ground.Efficient Fault Current Dissipation: The high conductivity of copper allows the grounding system to effectively handle fault currents, lightning strikes, or other electrical surges, preventing damage to equipment and reducing safety risks.

Quick Fault Response: The high conductivity of copper ensures that fault currents, lightning surges, or short circuits are swiftly directed to the ground, minimizing the risk of equipment failure, electrical fires, or electric shock hazards.Lower Ground Resistance: Copper's conductive properties ensure that the overall grounding resistance remains low, which is critical for enhancing safety by ensuring that dangerous currents are quickly dissipated, protecting both personnel and assets.

Stranded Wire Flexibility: Earthing copper stranded wire offers flexibility, making it easier to route through difficult or tight spaces in grounding installations. This adaptability does not compromise the wire’s conductivity and allows for efficient grounding in complex system layouts.Corrosion Resistance: Copper’s inherent resistance to corrosion, especially compared to other metals like steel, ensures long-lasting performance in various environmental conditions, such as humid or saline environments. This ensures that the earthing system maintains its conductivity over time without degradation.

Consistent Performance: Copper does not oxidize quickly like other metals, which means that its conductive properties remain consistent over time. This long-term stability helps ensure that the grounding system continues to perform efficiently for many years without frequent maintenance or replacement.Reduced Maintenance Needs: The durability of copper reduces the need for regular maintenance checks or replacements, providing a more cost-effective and reliable grounding solution in the long term.

Enhanced Earthing Effectiveness: The high conductivity of copper stranded wire ensures that the earthing system provides an efficient and stable ground path for electrical systems. This is crucial in applications where low-resistance grounding is required to ensure proper functioning and safety.Quick Response to Lightning Strikes: Copper’s efficient electrical conductivity makes it ideal for grounding lightning protection systems, allowing them to safely dissipate the high energy from lightning strikes into the ground without causing equipment damage or danger to people.

Strong and Stable Connections: Copper’s ability to form stable electrical connections reduces the likelihood of contact resistance, which can lead to power loss, overheating, and system failure. This stability ensures that the grounding system continues to operate optimally throughout its lifespan.Reduced Voltage Drops: Stable and low contact resistance helps minimize voltage drops across the system, ensuring that electrical equipment connected to the grounding system operates safely and efficiently.

English

English 简体中文

简体中文

.jpg)